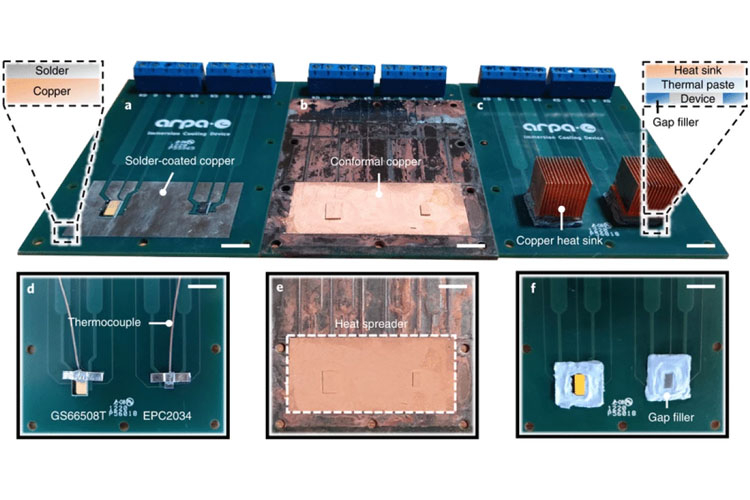

Scientists continue to search for the most efficient way to remove heat from electronic devices.In a new study, a team from the University of Illinois and University of California, Berkeley, has shown a new cooling method that's 740 percent more effective than using heat sinks, thermal pastes and other traditional heat dissipation methods.Conformal copper-coated circuit board in the center.One of the bottlenecks of heat dissipation was and still is the area where the heat sink contacts the surface of the chips or other electronic device surfaces that need to be cooled.Also, the lower part of the heat sink gets the warmest, which makes effective cooling of adjacent areas of the same PCB problematic.The scientists, whose study appeared in the prestigious journal Nature Electronics, solved both of these problems with one technique.The printed circuit board and electronic components on it were coated with a layer of poly-para-xylene (Parylene C).This is a dielectric material and a common coating for PCBs to protect against oxidation and other environmental influences.The second step was to apply a coating of copper over the dielectric.The copper was applied as the protective coating in a continuous layer.Thanks to the Parylene C layer, it could not short-circuit the electronic circuits and at the same time lay on all exposed surfaces on all sides, becoming something like a continuous heat sink and actually becoming one with the electronic components.First the copper was deposited from the vapor phase in a vacuum, which allowed a 20 nm thickness, and then 50 nm was added by electrolysis.Electrolysis allowed the copper to be deposited on all unaffected areas, allowing all surfaces on the board and chips to be coated in this manner.Image source: University of IllinoisExperiments have shown that such copper conformal coating handles the heat removal from electronic boards as well as traditional methods in the complete absence of heavy heat sinks.What's more, the coated boards can be installed in larger quantities in a limited enclosure volume and that will only improve heat dissipation.On the test bench, scientists showed that the heat dissipation efficiency could be improved by up to 8.4 times.The study confirmed that this conformal copper coating is suitable for air and water cooling systems, although further tests are needed to see how robust the solution will be in boiling water, boiling dielectric fluids, high voltage applications and in circuits more complex than the simple test stands used in the study.

0 Comments